Products Details

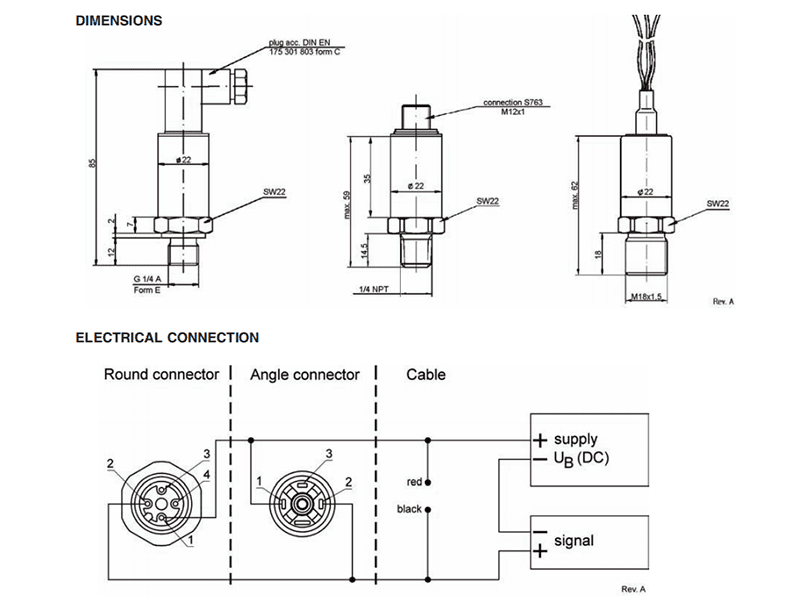

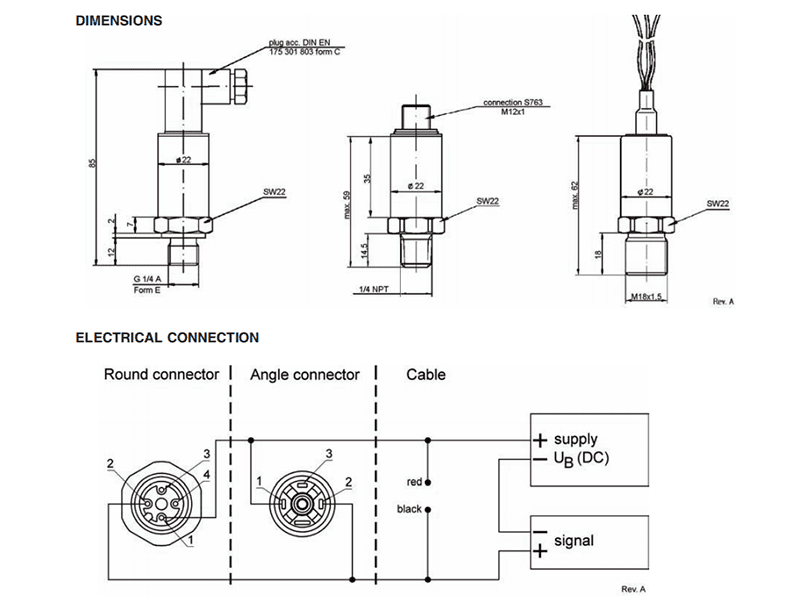

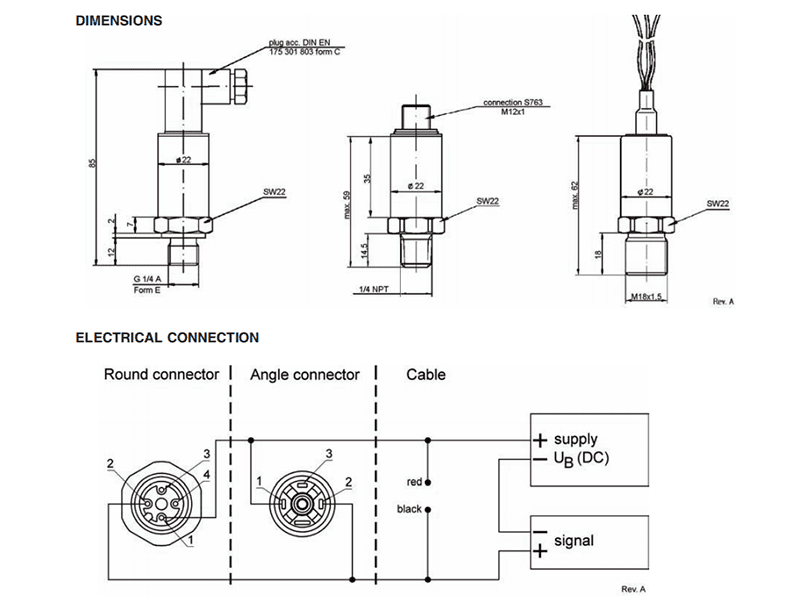

APPLICATIONS: KM 41 is ideally suited to address the demanding pressure sensing needs of the original equipment manufacturer in a multitude of applications, including: • Off-Road Equipment • Construction Machinery • HVAC/Refrigeration • Compressor Control • Pump Monitoring • Agricultural Implements • Diagnostic Kits • Engine Monitoring • Process Automation & Control • Hydraulic & Pneumatic Sensing FEATURES: • 1% Total Error Band Accuracy • Broad Temperature Capability • All-welded pressure construction • High EMI/RFI rating • Ranges .06 mPa through 200 mPa • IP 65 Ingress rating The Ashcroft KM41 pressure transducer combines proven polysilicon thin film sen�sor technology with a high performance ASIC to provide a highly accurate and sta�ble transducer. The 17-4PH stainless steel sensor is electron beam welded to a stain�less steel pressure fitting which provides excellent overpressure capability and out�standing durability in high shock and vibra�tion applications. Calibration via digital compensation results in an extremely accurate instrument over a wide tempera�ture range. The KM41 design is well suited for demanding, high cycle, hydraulic and pneumatic applications found onboard mobile hydraulic equipment. PERFORMANCE SPECIFICATIONS: Ref. Condition 21°C ±1°C (72°F ±2°F) Accuracy: Total Error Band includes combined effects of temper�ature, non-linearity (Terminal Point Method), hysteresis, non repeatabilty, zero offset and span setting errors ±1% of Span: From –20 to 85ºC (–4 to 185ºF) ±3.0% of Span: From –40 to -20ºC (–40 to –4ºF) ±2.5% of Span: From 85 to 125ºC (185 to 257ºF) Note: Static accuracy ±0.5% of span BFSL (Best Fit Straight Line Method); includes non-linearity, hysteresis and non-repeatable effects at reference temperature 72°F (21°C) Stability: Less than ±0.25% span/year Durability: Tested to 50 million cycles ENVIRONMENTAL SPECIFICATIONS: Temperature: Compensated –40 to 125°C (–40 to 257°F) Operating –40 to 125°C (–40 to 257°F) Storage –40 to 125°C (–40 to 257°F) Humidity: 0 to 100% R.H., no effect FUNCTIONAL SPECIFICATIONS Select from over 25 pressure ranges starting at 30 psi and running through 20,000 psi gauge. Compound (vacuum & pressure) ranges are also available, see “To Order” on back. Overpressure (F.S.): Proof Burst 35 MPa 200% 500% 70 MPa 150% 240% 200 MPa 120% 240% Vibration: Testing according to IEC 68-2-6 and IEC 68-2-36 Shock: Testing according to IEC 68-2-32 Drop Test: Withstands 1 meter on steel plate Response Time: Less than 1 msec Warm-up Time: Less than 500 msec typical Position Effect: Less than ±0.01% span, typical ELECTRICAL SPECIFICATIONS Output Signals Available: Supply Voltage Output Excitation Current 0-10 Vdc, 3 wire 12-32 Vdc 5mA Ratiometric Output: 0.5-4.5 Vdc, 3 wire 5 Vdc ±0.5 Vdc 4mA Current Output: 4-20mA, 2 wire 12-32 Vdc Reverse Polarity & Miswired Protected: Yes Insulation Breakdown Voltage: 100 Vac Insulation Resistance: Greater than 100 megohms at 100 Vdc CE Compliance: Testing to DIN EN 55011 and DIN 61000-4-3 PHYSICAL SPECIFICATIONS Pressure Connection: 304 stainless steel Sensor Material: 17-4PH SS Housing: Stainless steel Available Process Connections (Male): G1 ⁄4A, Form E, 1 ⁄4 BSP, 1 ⁄4 NPT For other connections consult factory Ingress Rating: IP65 Weight: 90g ELECTRICAL TERMINATION • Shielded Cable: 3´ standard, 24 AWG, PVC Jacket • Metri-Pack 150 series* • MVS DIN EN 175 301 803 *Metri-Pack is a trademark of Delphi Packard Electric Systems

Auxiliary machinery with auto loader,

Driver,

Servo System,

Wpc 8mm Vinyl Plank Flooring Pvc Flooring,

5050 Strip 300led,

Eva Injection Moulding Machine,

Light Inflatable Flower,

Indoor Display Led,

Full-Auto Injection Molding Machine,

Plastic Injection Molding Machine,