Products Details

Gefran is the world leader with forty years in the design and production of solutions for measuring, controlling, and driving industrial production processes.We have branches in 14 countries and a network of over 80 worldwide distributors. QUALITY AND TECHNOLOGY Gefran has been designing and manufacturing position sensors for over 40 years. More than a million transducers installed and an in-depth knowledge of measurement processes guarantee performance and an elevated quality/price ratio. Gefran is the manufacturer of the sensitive component of its transducers and is thus able to guarantee product reliability and precision of measurement as well as the flexibility in customization for the client. Gefran’s position transducers are based on two different technologies: first, potentiometric technology providing a broad flexible range developed over the years; second, magnetostrictive technology that provides fully-developed solutions with superior performance due to the non-contact measurement system. Characteristics of Gefran’s position transducers: - Measures the definite position: upon switching the system on, the transducer immediately reads the actual position without having to perform any mechanical repositioning. - Extensive lifespan: from 100 million movements of the potentiometric transducers to the virtually unlimited lifespan of the magnetostrictive transducers as a result of the lack of contact between the transducer and its position reader. - High resolution output signal: practically infinite for the potentiometers and 2μ for the magnetostrictive transducers. - Easy installation and simple connection to the most common tools and PLCs on the market. - Manages cursors using the same transducer and reads the speed of movement (MK4-C / IK4-C in CANopen up to 2 cursors; MK4-P / IK4-P Profibus interface up to 4 cursors;analogue; MK4-A up to a maximum of 2 cursors). - Rod from 10 mm up to 4000 mm SERVICES: A team of Gefran experts works with the customer to select the ideal product for its application and to help install and configure devices. Gefran offers a wide range of courses at different levels for the technical-commercial study of the Gefran product range as well as specific courses on demand.

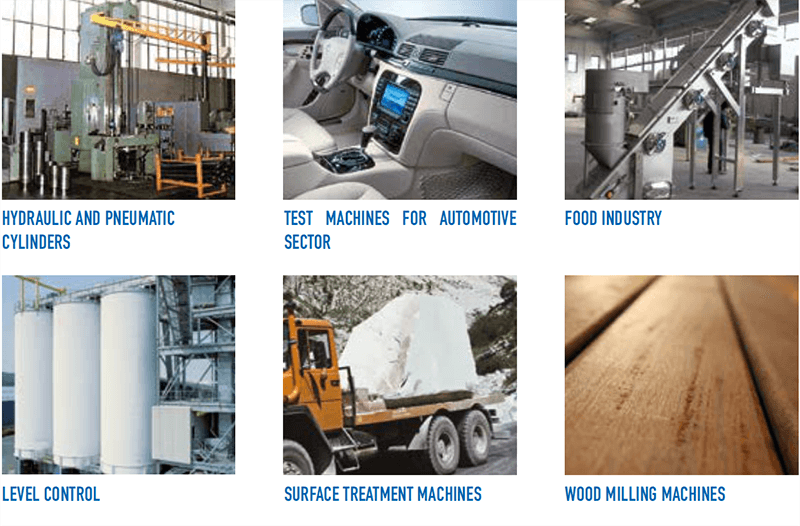

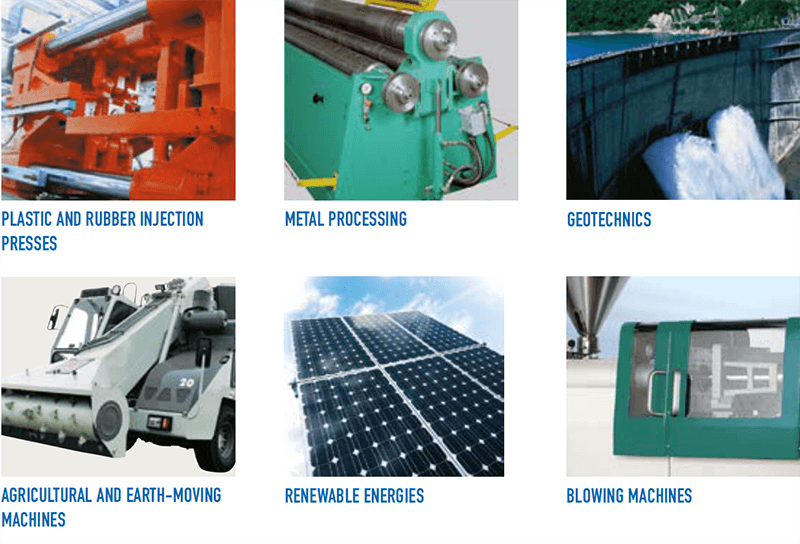

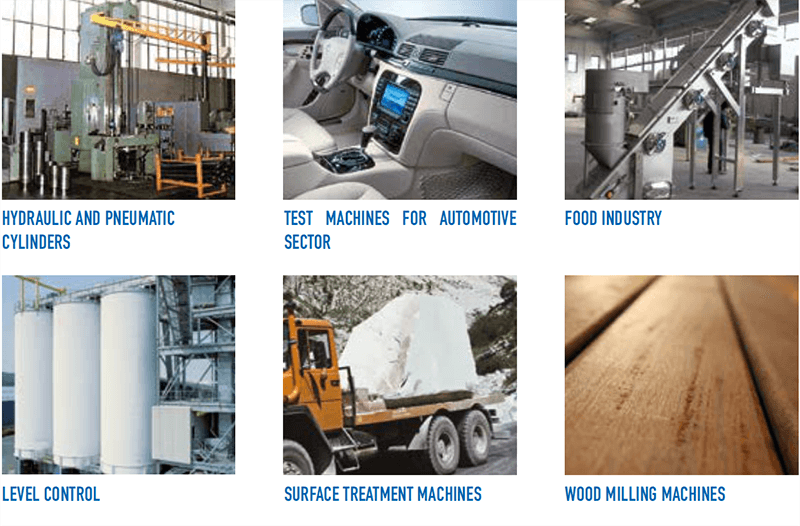

Gefran is the world leader with forty years in the design and production of solutions for measuring, controlling, and driving industrial production processes.We have branches in 14 countries and a network of over 80 worldwide distributors. QUALITY AND TECHNOLOGY Gefran has been designing and manufacturing position sensors for over 40 years. More than a million transducers installed and an in-depth knowledge of measurement processes guarantee performance and an elevated quality/price ratio. Gefran is the manufacturer of the sensitive component of its transducers and is thus able to guarantee product reliability and precision of measurement as well as the flexibility in customization for the client. Gefran’s position transducers are based on two different technologies: first, potentiometric technology providing a broad flexible range developed over the years; second, magnetostrictive technology that provides fully-developed solutions with superior performance due to the non-contact measurement system. Characteristics of Gefran’s position transducers: - Measures the definite position: upon switching the system on, the transducer immediately reads the actual position without having to perform any mechanical repositioning. - Extensive lifespan: from 100 million movements of the potentiometric transducers to the virtually unlimited lifespan of the magnetostrictive transducers as a result of the lack of contact between the transducer and its position reader. - High resolution output signal: practically infinite for the potentiometers and 2μ for the magnetostrictive transducers. - Easy installation and simple connection to the most common tools and PLCs on the market. - Manages cursors using the same transducer and reads the speed of movement (MK4-C / IK4-C in CANopen up to 2 cursors; MK4-P / IK4-P Profibus interface up to 4 cursors;analogue; MK4-A up to a maximum of 2 cursors). - Rod from 10 mm up to 4000 mm SERVICES: A team of Gefran experts works with the customer to select the ideal product for its application and to help install and configure devices. Gefran offers a wide range of courses at different levels for the technical-commercial study of the Gefran product range as well as specific courses on demand.  APPLICATIONS:

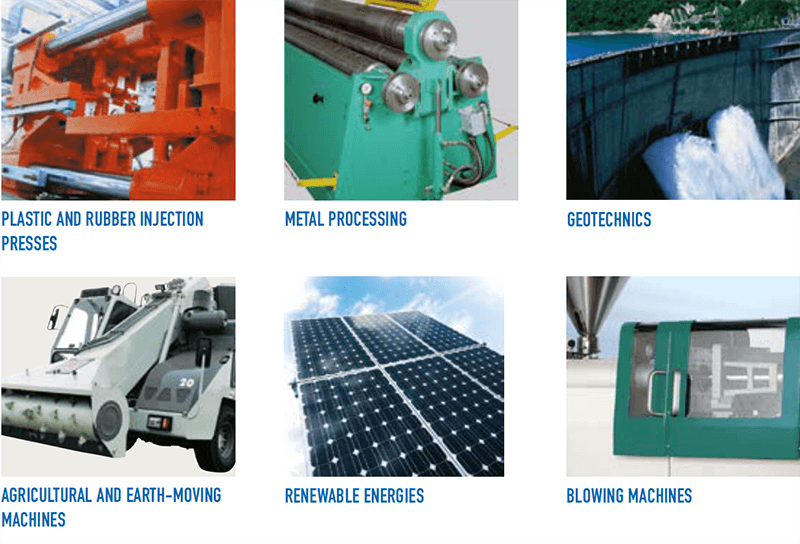

APPLICATIONS:

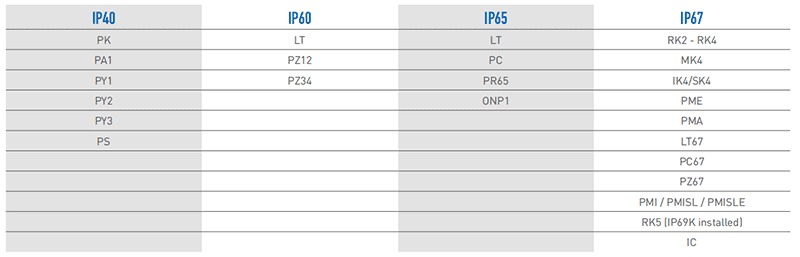

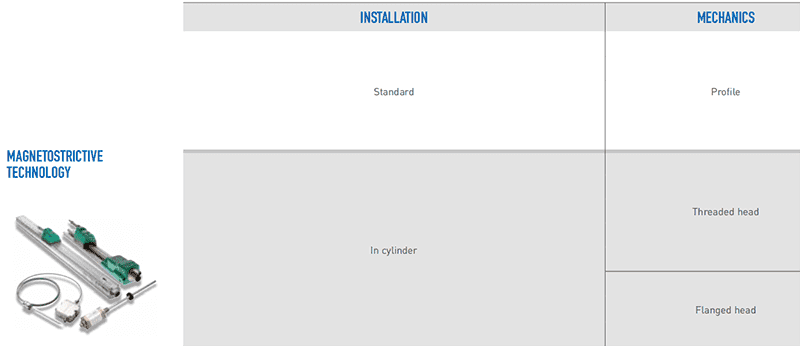

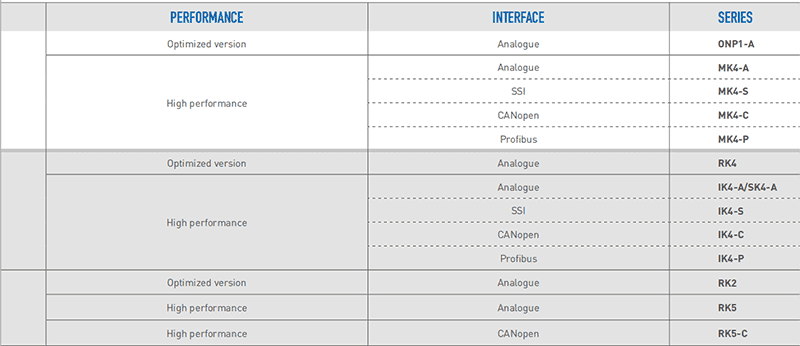

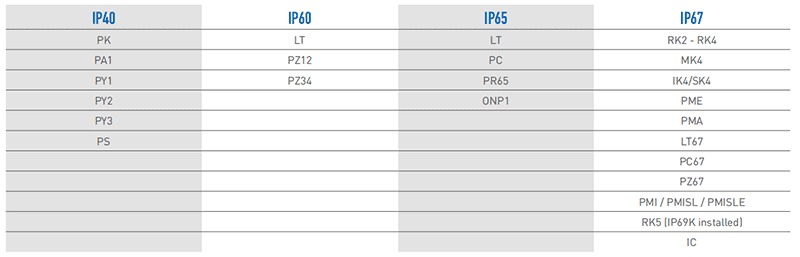

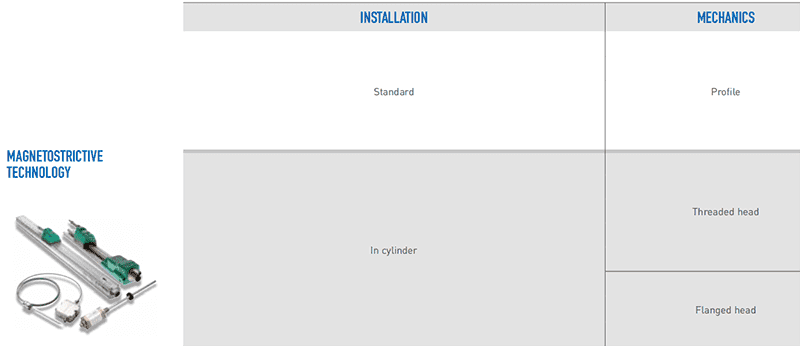

THE MAGNETOSTRICTIVE SOLUTION: Constant and systematic is the activity of researching and innovating in order to improve and optimize the performance of the position sensors with magnetostrictive technology.Patented by Gefran, ONDA is the sensing element which was designed with the target to simplify and optimize the transduction element. These are the main characteristics of ONDA: - a simplified sensing element that allows to further reduce the transducer dimensions - a simple and modular structure in order to obtain a greater reliability and ease maintenance - unique solutions which guarantee maximum performance in its class. GUIDE TO SELECTION: LEVEL OF PROTECTION According to the structure and technology used, GEFRAN’s linear position transducers are able to provide different levels of protection against dust and liquids. Ranges from IP40 to IP67 can be chosen, according to the following table:

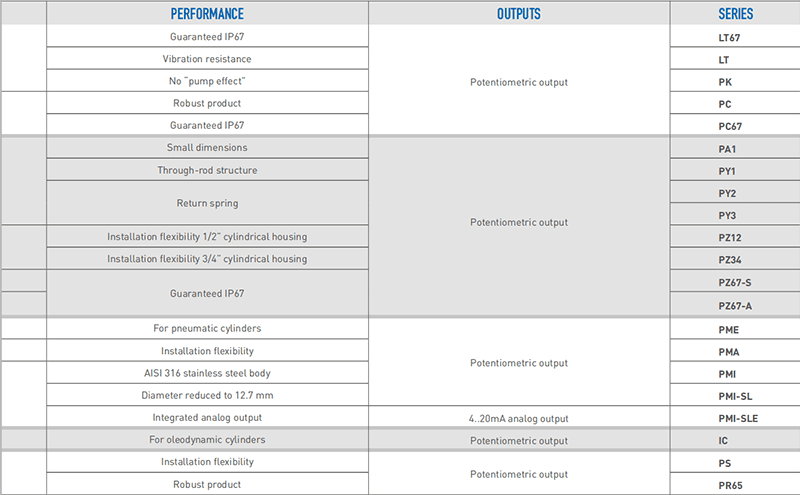

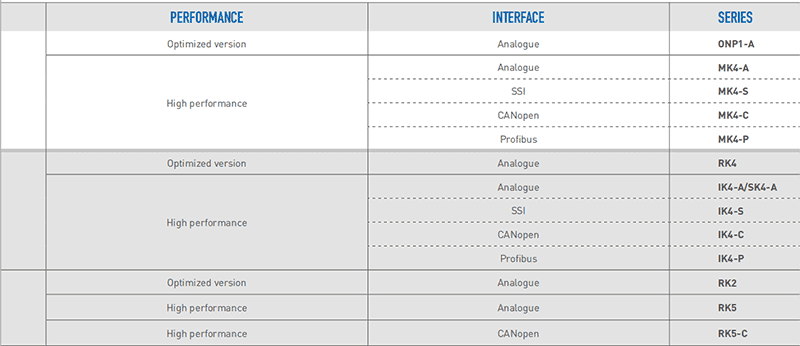

THE MAGNETOSTRICTIVE SOLUTION: Constant and systematic is the activity of researching and innovating in order to improve and optimize the performance of the position sensors with magnetostrictive technology.Patented by Gefran, ONDA is the sensing element which was designed with the target to simplify and optimize the transduction element. These are the main characteristics of ONDA: - a simplified sensing element that allows to further reduce the transducer dimensions - a simple and modular structure in order to obtain a greater reliability and ease maintenance - unique solutions which guarantee maximum performance in its class. GUIDE TO SELECTION: LEVEL OF PROTECTION According to the structure and technology used, GEFRAN’s linear position transducers are able to provide different levels of protection against dust and liquids. Ranges from IP40 to IP67 can be chosen, according to the following table:  COMMUNICATION INTERFACE: The potentiometers provide a ratiometric voltage output. This means that the range of output voltage depends on the voltage used to power the transducer. Use the sensor as a voltage divider with a max current across the cursor Ic≤ 0.1mA. WARNING! The potentiometer must not be used as a variable resistor. If you wish to obtain a conditioned signal 0..10 Vdc or 4..20 mA as the potentiometer’s output, a PCIR signal conditioner can be connected to the output of the device. Available also the version the potentiometric version PMISLE with integrated analogue output 4..20mA. The magnetostrictive transducers, on the other hand, allow you to choose the output interface that best suits your application needs: - analogue voltage output: 0..5Vcc/5..0Vcc, 0..10Vcc/10..0Vcc - analogue current output: 0..20mA, 4..20mA - SSI output: 16, 21, 24, 25 bit binary or Gray code - CANopen output: CiA DP 3.01 rel.4.0 and DS406 - Profibus output: DPV0 on RS485 according to IEC 61158

COMMUNICATION INTERFACE: The potentiometers provide a ratiometric voltage output. This means that the range of output voltage depends on the voltage used to power the transducer. Use the sensor as a voltage divider with a max current across the cursor Ic≤ 0.1mA. WARNING! The potentiometer must not be used as a variable resistor. If you wish to obtain a conditioned signal 0..10 Vdc or 4..20 mA as the potentiometer’s output, a PCIR signal conditioner can be connected to the output of the device. Available also the version the potentiometric version PMISLE with integrated analogue output 4..20mA. The magnetostrictive transducers, on the other hand, allow you to choose the output interface that best suits your application needs: - analogue voltage output: 0..5Vcc/5..0Vcc, 0..10Vcc/10..0Vcc - analogue current output: 0..20mA, 4..20mA - SSI output: 16, 21, 24, 25 bit binary or Gray code - CANopen output: CiA DP 3.01 rel.4.0 and DS406 - Profibus output: DPV0 on RS485 according to IEC 61158  POSITION TRANSDUCERS:

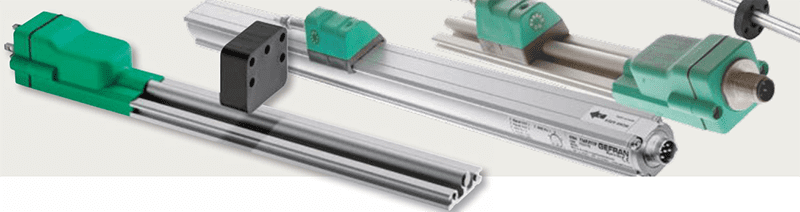

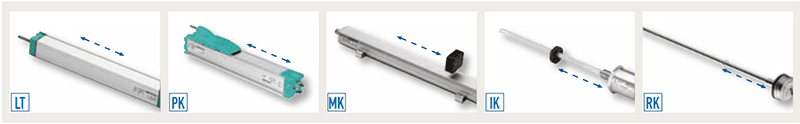

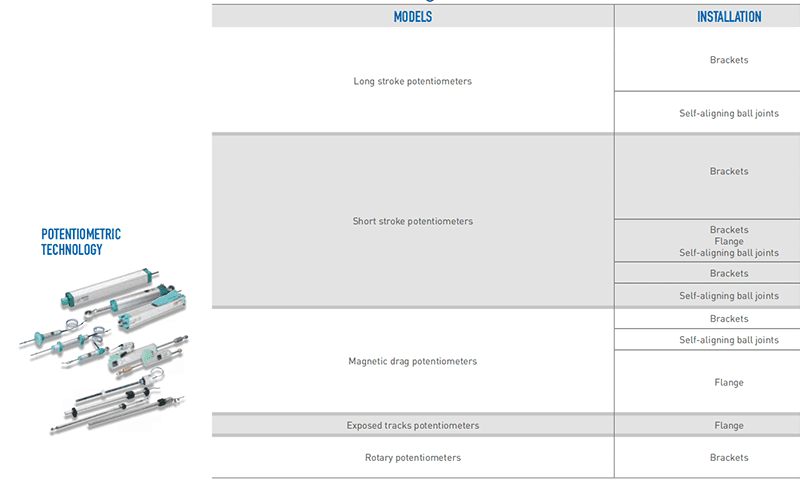

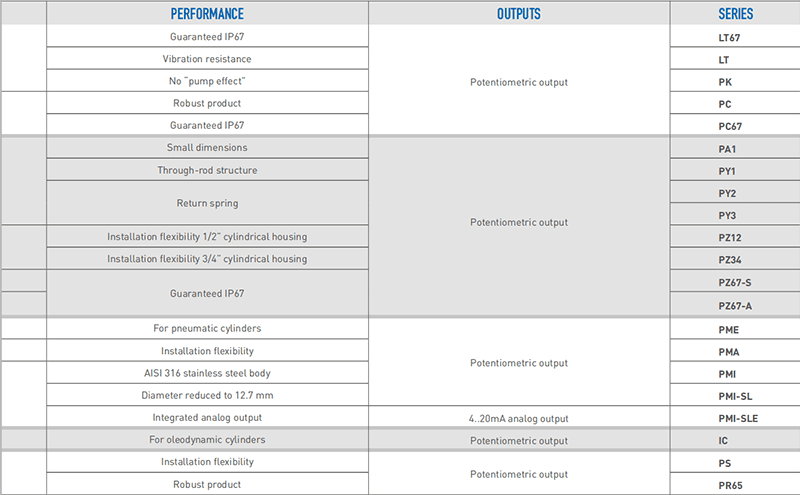

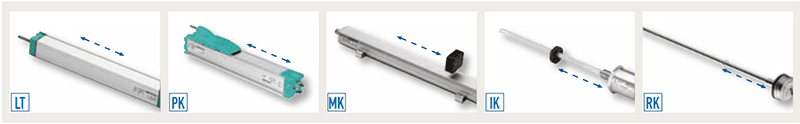

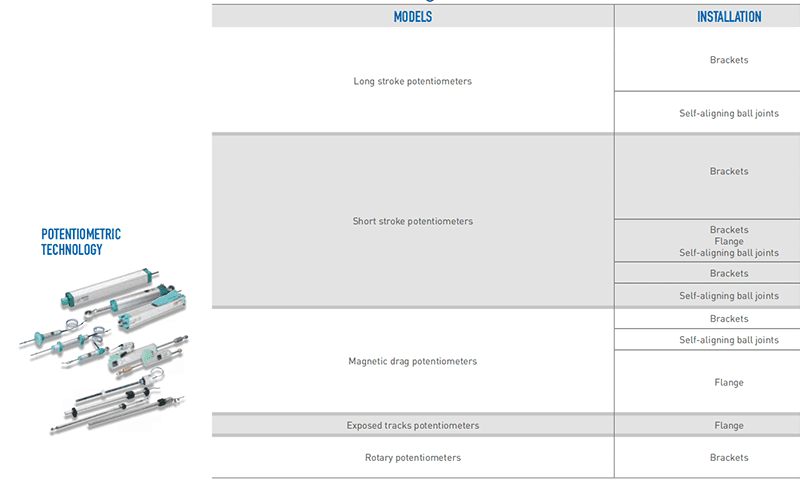

POSITION TRANSDUCERS:  STROKE LENGTH: UP TO 4000 mm When choosing a transducer, it is important to remember that two different strokes exist: - Mechanical stroke: the actual shift that the transducer’s cursor is able to make; - Useful electrical stroke: the part of the mechanical stroke in whichtransducer linearity is guaranteed. Therefore, when designing an application, you should choose a transducer with a useful electrical stroke that is equal to or greater than the maximum displacement carried out by the moving part. TYPES OF ACTUATORS: In order to measure the displacement of an object, the transducer has a mobile part that is usually attached to the object itself. Two types of mobile parts are normally used: - stem: the classical system used by potentiometers which consists of a rod connected to the transducer’s body that transmits the shift to the inner parts of the sensor; - cursor: a system that provides for more compact solutions thanks to the use of a cursor which becomes integral with the movingpart to be measured. Some models of potentiometers, such as the PME series, are characterized by an external magnetic actuator linked to an internal measurement cursor. The magnetic cursor replaces the shaft , making the instrument even more compact. 3 FASTENING SYSTEMS: Three types of supports can be used to install the transducer: - brackets: the most traditional method; a free surface and two or more brackets according to the length of the transducer are requiredto install the transducer; - flanges: ideal for applications where the stem needs to pass through a hole and the transducer needs to be fixed on the walls of the hole; the conditions of use need to be considered, especially in relation to high strokes; - self-aligning articulated joints: used to fasten the ends of the transducer directly to the moving parts; other fastening points canbe eliminated and offset movements can be measured; this system is not intended for particularly long strokes.

STROKE LENGTH: UP TO 4000 mm When choosing a transducer, it is important to remember that two different strokes exist: - Mechanical stroke: the actual shift that the transducer’s cursor is able to make; - Useful electrical stroke: the part of the mechanical stroke in whichtransducer linearity is guaranteed. Therefore, when designing an application, you should choose a transducer with a useful electrical stroke that is equal to or greater than the maximum displacement carried out by the moving part. TYPES OF ACTUATORS: In order to measure the displacement of an object, the transducer has a mobile part that is usually attached to the object itself. Two types of mobile parts are normally used: - stem: the classical system used by potentiometers which consists of a rod connected to the transducer’s body that transmits the shift to the inner parts of the sensor; - cursor: a system that provides for more compact solutions thanks to the use of a cursor which becomes integral with the movingpart to be measured. Some models of potentiometers, such as the PME series, are characterized by an external magnetic actuator linked to an internal measurement cursor. The magnetic cursor replaces the shaft , making the instrument even more compact. 3 FASTENING SYSTEMS: Three types of supports can be used to install the transducer: - brackets: the most traditional method; a free surface and two or more brackets according to the length of the transducer are requiredto install the transducer; - flanges: ideal for applications where the stem needs to pass through a hole and the transducer needs to be fixed on the walls of the hole; the conditions of use need to be considered, especially in relation to high strokes; - self-aligning articulated joints: used to fasten the ends of the transducer directly to the moving parts; other fastening points canbe eliminated and offset movements can be measured; this system is not intended for particularly long strokes.  GUIDE TO SELECTION OF TRANSDUCER:

GUIDE TO SELECTION OF TRANSDUCER:

POSITION TRANSDUCERS

POSITION TRANSDUCERS

Efficient Plastic Injection Molding,

Wood Grain Commerical Pvc Floor,

Mini Plastic Injection Machine,

Hydraulic Valves,

Injection Blow Molding Machine,

Small Injection Molding Machine Price,

Silicone Rubber Injection Molding Machine,

Niigata Used Injection Molding Machine,

Luxury Commerical Pvc Flooring,

Plastic Injection Molding Machine Price,

Gefran is the world leader with forty years in the design and production of solutions for measuring, controlling, and driving industrial production processes.We have branches in 14 countries and a network of over 80 worldwide distributors. QUALITY AND TECHNOLOGY Gefran has been designing and manufacturing position sensors for over 40 years. More than a million transducers installed and an in-depth knowledge of measurement processes guarantee performance and an elevated quality/price ratio. Gefran is the manufacturer of the sensitive component of its transducers and is thus able to guarantee product reliability and precision of measurement as well as the flexibility in customization for the client. Gefran’s position transducers are based on two different technologies: first, potentiometric technology providing a broad flexible range developed over the years; second, magnetostrictive technology that provides fully-developed solutions with superior performance due to the non-contact measurement system. Characteristics of Gefran’s position transducers: - Measures the definite position: upon switching the system on, the transducer immediately reads the actual position without having to perform any mechanical repositioning. - Extensive lifespan: from 100 million movements of the potentiometric transducers to the virtually unlimited lifespan of the magnetostrictive transducers as a result of the lack of contact between the transducer and its position reader. - High resolution output signal: practically infinite for the potentiometers and 2μ for the magnetostrictive transducers. - Easy installation and simple connection to the most common tools and PLCs on the market. - Manages cursors using the same transducer and reads the speed of movement (MK4-C / IK4-C in CANopen up to 2 cursors; MK4-P / IK4-P Profibus interface up to 4 cursors;analogue; MK4-A up to a maximum of 2 cursors). - Rod from 10 mm up to 4000 mm SERVICES: A team of Gefran experts works with the customer to select the ideal product for its application and to help install and configure devices. Gefran offers a wide range of courses at different levels for the technical-commercial study of the Gefran product range as well as specific courses on demand.

Gefran is the world leader with forty years in the design and production of solutions for measuring, controlling, and driving industrial production processes.We have branches in 14 countries and a network of over 80 worldwide distributors. QUALITY AND TECHNOLOGY Gefran has been designing and manufacturing position sensors for over 40 years. More than a million transducers installed and an in-depth knowledge of measurement processes guarantee performance and an elevated quality/price ratio. Gefran is the manufacturer of the sensitive component of its transducers and is thus able to guarantee product reliability and precision of measurement as well as the flexibility in customization for the client. Gefran’s position transducers are based on two different technologies: first, potentiometric technology providing a broad flexible range developed over the years; second, magnetostrictive technology that provides fully-developed solutions with superior performance due to the non-contact measurement system. Characteristics of Gefran’s position transducers: - Measures the definite position: upon switching the system on, the transducer immediately reads the actual position without having to perform any mechanical repositioning. - Extensive lifespan: from 100 million movements of the potentiometric transducers to the virtually unlimited lifespan of the magnetostrictive transducers as a result of the lack of contact between the transducer and its position reader. - High resolution output signal: practically infinite for the potentiometers and 2μ for the magnetostrictive transducers. - Easy installation and simple connection to the most common tools and PLCs on the market. - Manages cursors using the same transducer and reads the speed of movement (MK4-C / IK4-C in CANopen up to 2 cursors; MK4-P / IK4-P Profibus interface up to 4 cursors;analogue; MK4-A up to a maximum of 2 cursors). - Rod from 10 mm up to 4000 mm SERVICES: A team of Gefran experts works with the customer to select the ideal product for its application and to help install and configure devices. Gefran offers a wide range of courses at different levels for the technical-commercial study of the Gefran product range as well as specific courses on demand.  APPLICATIONS:

APPLICATIONS:

THE MAGNETOSTRICTIVE SOLUTION: Constant and systematic is the activity of researching and innovating in order to improve and optimize the performance of the position sensors with magnetostrictive technology.Patented by Gefran, ONDA is the sensing element which was designed with the target to simplify and optimize the transduction element. These are the main characteristics of ONDA: - a simplified sensing element that allows to further reduce the transducer dimensions - a simple and modular structure in order to obtain a greater reliability and ease maintenance - unique solutions which guarantee maximum performance in its class. GUIDE TO SELECTION: LEVEL OF PROTECTION According to the structure and technology used, GEFRAN’s linear position transducers are able to provide different levels of protection against dust and liquids. Ranges from IP40 to IP67 can be chosen, according to the following table:

THE MAGNETOSTRICTIVE SOLUTION: Constant and systematic is the activity of researching and innovating in order to improve and optimize the performance of the position sensors with magnetostrictive technology.Patented by Gefran, ONDA is the sensing element which was designed with the target to simplify and optimize the transduction element. These are the main characteristics of ONDA: - a simplified sensing element that allows to further reduce the transducer dimensions - a simple and modular structure in order to obtain a greater reliability and ease maintenance - unique solutions which guarantee maximum performance in its class. GUIDE TO SELECTION: LEVEL OF PROTECTION According to the structure and technology used, GEFRAN’s linear position transducers are able to provide different levels of protection against dust and liquids. Ranges from IP40 to IP67 can be chosen, according to the following table:  COMMUNICATION INTERFACE: The potentiometers provide a ratiometric voltage output. This means that the range of output voltage depends on the voltage used to power the transducer. Use the sensor as a voltage divider with a max current across the cursor Ic≤ 0.1mA. WARNING! The potentiometer must not be used as a variable resistor. If you wish to obtain a conditioned signal 0..10 Vdc or 4..20 mA as the potentiometer’s output, a PCIR signal conditioner can be connected to the output of the device. Available also the version the potentiometric version PMISLE with integrated analogue output 4..20mA. The magnetostrictive transducers, on the other hand, allow you to choose the output interface that best suits your application needs: - analogue voltage output: 0..5Vcc/5..0Vcc, 0..10Vcc/10..0Vcc - analogue current output: 0..20mA, 4..20mA - SSI output: 16, 21, 24, 25 bit binary or Gray code - CANopen output: CiA DP 3.01 rel.4.0 and DS406 - Profibus output: DPV0 on RS485 according to IEC 61158

COMMUNICATION INTERFACE: The potentiometers provide a ratiometric voltage output. This means that the range of output voltage depends on the voltage used to power the transducer. Use the sensor as a voltage divider with a max current across the cursor Ic≤ 0.1mA. WARNING! The potentiometer must not be used as a variable resistor. If you wish to obtain a conditioned signal 0..10 Vdc or 4..20 mA as the potentiometer’s output, a PCIR signal conditioner can be connected to the output of the device. Available also the version the potentiometric version PMISLE with integrated analogue output 4..20mA. The magnetostrictive transducers, on the other hand, allow you to choose the output interface that best suits your application needs: - analogue voltage output: 0..5Vcc/5..0Vcc, 0..10Vcc/10..0Vcc - analogue current output: 0..20mA, 4..20mA - SSI output: 16, 21, 24, 25 bit binary or Gray code - CANopen output: CiA DP 3.01 rel.4.0 and DS406 - Profibus output: DPV0 on RS485 according to IEC 61158  POSITION TRANSDUCERS:

POSITION TRANSDUCERS:  STROKE LENGTH: UP TO 4000 mm When choosing a transducer, it is important to remember that two different strokes exist: - Mechanical stroke: the actual shift that the transducer’s cursor is able to make; - Useful electrical stroke: the part of the mechanical stroke in whichtransducer linearity is guaranteed. Therefore, when designing an application, you should choose a transducer with a useful electrical stroke that is equal to or greater than the maximum displacement carried out by the moving part. TYPES OF ACTUATORS: In order to measure the displacement of an object, the transducer has a mobile part that is usually attached to the object itself. Two types of mobile parts are normally used: - stem: the classical system used by potentiometers which consists of a rod connected to the transducer’s body that transmits the shift to the inner parts of the sensor; - cursor: a system that provides for more compact solutions thanks to the use of a cursor which becomes integral with the movingpart to be measured. Some models of potentiometers, such as the PME series, are characterized by an external magnetic actuator linked to an internal measurement cursor. The magnetic cursor replaces the shaft , making the instrument even more compact. 3 FASTENING SYSTEMS: Three types of supports can be used to install the transducer: - brackets: the most traditional method; a free surface and two or more brackets according to the length of the transducer are requiredto install the transducer; - flanges: ideal for applications where the stem needs to pass through a hole and the transducer needs to be fixed on the walls of the hole; the conditions of use need to be considered, especially in relation to high strokes; - self-aligning articulated joints: used to fasten the ends of the transducer directly to the moving parts; other fastening points canbe eliminated and offset movements can be measured; this system is not intended for particularly long strokes.

STROKE LENGTH: UP TO 4000 mm When choosing a transducer, it is important to remember that two different strokes exist: - Mechanical stroke: the actual shift that the transducer’s cursor is able to make; - Useful electrical stroke: the part of the mechanical stroke in whichtransducer linearity is guaranteed. Therefore, when designing an application, you should choose a transducer with a useful electrical stroke that is equal to or greater than the maximum displacement carried out by the moving part. TYPES OF ACTUATORS: In order to measure the displacement of an object, the transducer has a mobile part that is usually attached to the object itself. Two types of mobile parts are normally used: - stem: the classical system used by potentiometers which consists of a rod connected to the transducer’s body that transmits the shift to the inner parts of the sensor; - cursor: a system that provides for more compact solutions thanks to the use of a cursor which becomes integral with the movingpart to be measured. Some models of potentiometers, such as the PME series, are characterized by an external magnetic actuator linked to an internal measurement cursor. The magnetic cursor replaces the shaft , making the instrument even more compact. 3 FASTENING SYSTEMS: Three types of supports can be used to install the transducer: - brackets: the most traditional method; a free surface and two or more brackets according to the length of the transducer are requiredto install the transducer; - flanges: ideal for applications where the stem needs to pass through a hole and the transducer needs to be fixed on the walls of the hole; the conditions of use need to be considered, especially in relation to high strokes; - self-aligning articulated joints: used to fasten the ends of the transducer directly to the moving parts; other fastening points canbe eliminated and offset movements can be measured; this system is not intended for particularly long strokes.  GUIDE TO SELECTION OF TRANSDUCER:

GUIDE TO SELECTION OF TRANSDUCER:

POSITION TRANSDUCERS

POSITION TRANSDUCERS