Products Details

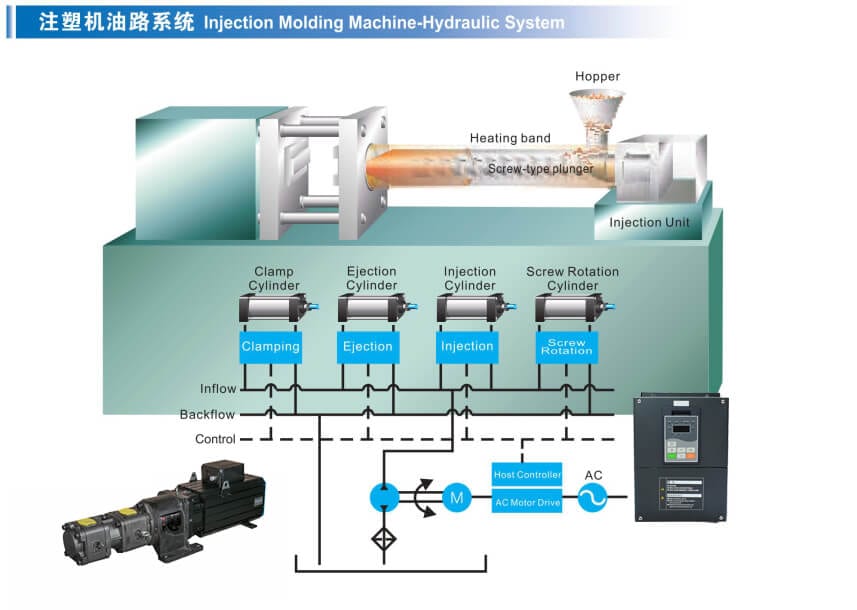

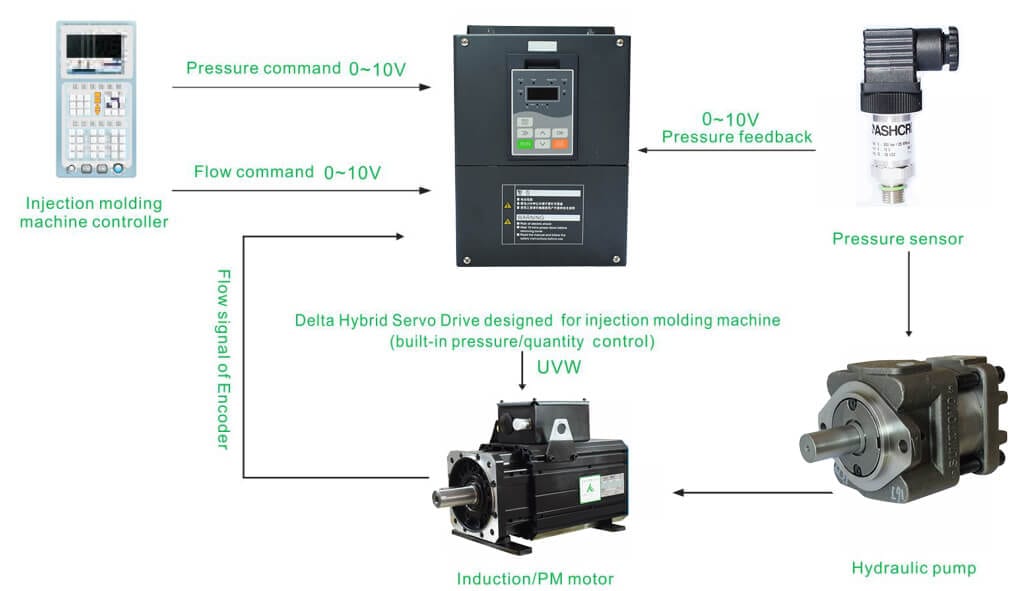

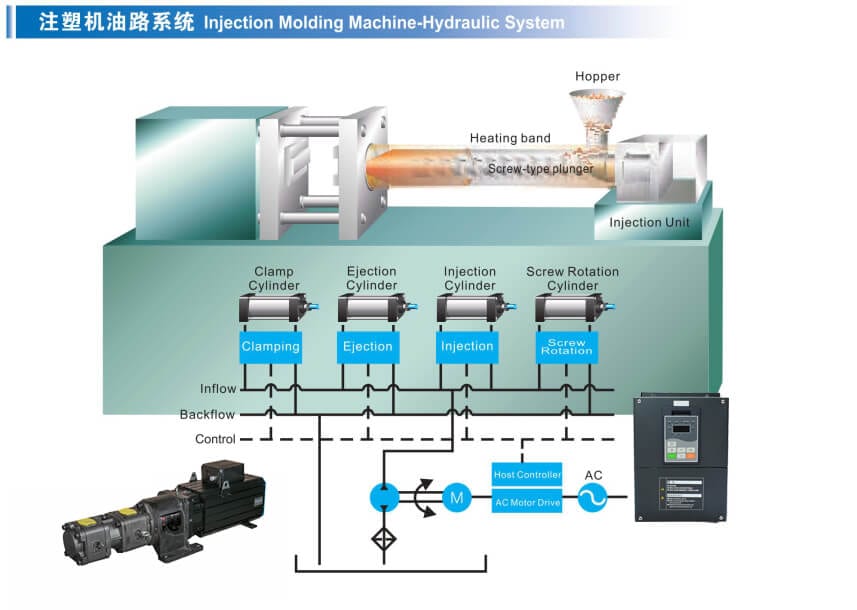

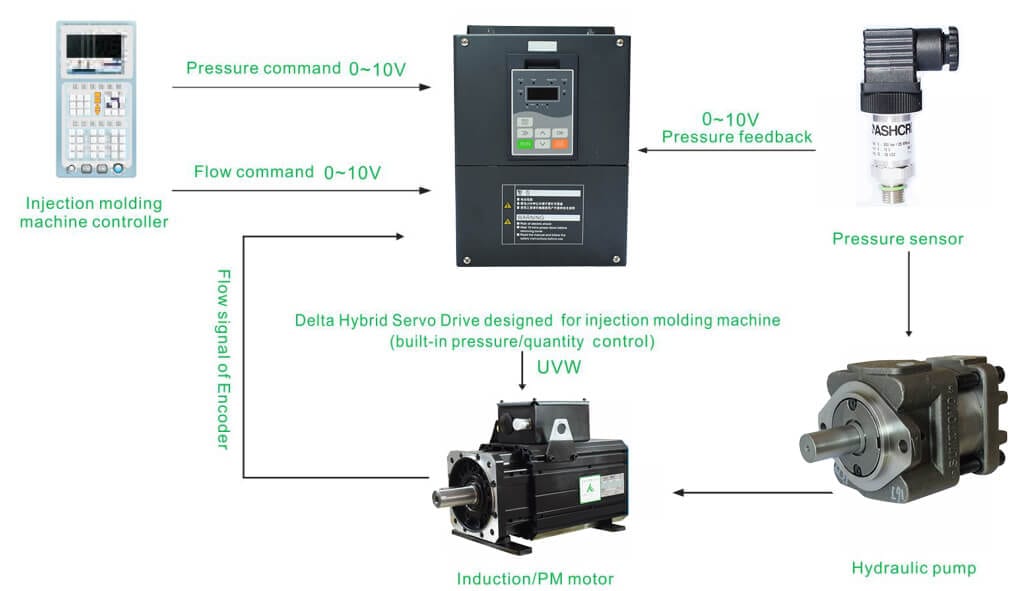

Servo Energy Saving System High response,high torque servo drive motor with pressure,flow closed loop control,so that the whole reaction speed,control accuracy,energy efficiency greatly improved.Compared with the general market,the servo energy-saving injection molding machine has the advantages of higher repeatability,smaller pressure flow fluctuation,more obvious energy saving effect,and faster response speed.  Structure of Servo System

Structure of Servo System  Our service Pre-sale : (1) Professional suggestions (raw material matching, machine selection, plan The condition of building factory, feasibility analysis for brick machine production line) (2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick) (3) Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you. (4) Introduce the company file, product categories and production process. Sale: (1) Update the production scheduling in time (2) Quality supervision (3) Product acceptance (4) Shipping on time After-sale: (1) The engineer will guide to carry out the plant at the clients side if needed. (2) Set up, fix, and operate (3) offer training to the operator until they are satisfied at clients side. (4) Skill support the whole using life. (5) Recall clients regularly ,get feedback in time ,keep well communication with each other.

Our service Pre-sale : (1) Professional suggestions (raw material matching, machine selection, plan The condition of building factory, feasibility analysis for brick machine production line) (2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick) (3) Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you. (4) Introduce the company file, product categories and production process. Sale: (1) Update the production scheduling in time (2) Quality supervision (3) Product acceptance (4) Shipping on time After-sale: (1) The engineer will guide to carry out the plant at the clients side if needed. (2) Set up, fix, and operate (3) offer training to the operator until they are satisfied at clients side. (4) Skill support the whole using life. (5) Recall clients regularly ,get feedback in time ,keep well communication with each other.

Auto loader for auxiliary equipment,

Energy Saving Servo System,

Injection Molding Machine Oil Filter,

Injection Plastic Machine,

Hybrid double-shot injection molding machine,

Plc Control Injection Molding Machine,

Syringe Injection Molding Machine,

Benchtop Plastic Injection Molding Machine,

Dc Motor,

Submersible pressure sensors,

Structure of Servo System

Structure of Servo System  Our service Pre-sale : (1) Professional suggestions (raw material matching, machine selection, plan The condition of building factory, feasibility analysis for brick machine production line) (2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick) (3) Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you. (4) Introduce the company file, product categories and production process. Sale: (1) Update the production scheduling in time (2) Quality supervision (3) Product acceptance (4) Shipping on time After-sale: (1) The engineer will guide to carry out the plant at the clients side if needed. (2) Set up, fix, and operate (3) offer training to the operator until they are satisfied at clients side. (4) Skill support the whole using life. (5) Recall clients regularly ,get feedback in time ,keep well communication with each other.

Our service Pre-sale : (1) Professional suggestions (raw material matching, machine selection, plan The condition of building factory, feasibility analysis for brick machine production line) (2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick) (3) Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you. (4) Introduce the company file, product categories and production process. Sale: (1) Update the production scheduling in time (2) Quality supervision (3) Product acceptance (4) Shipping on time After-sale: (1) The engineer will guide to carry out the plant at the clients side if needed. (2) Set up, fix, and operate (3) offer training to the operator until they are satisfied at clients side. (4) Skill support the whole using life. (5) Recall clients regularly ,get feedback in time ,keep well communication with each other.